X-CYCLONE® Technology

Our aerosol separation technology provides for perfectly clean air at your workplaces

The X-CYCLONE® Aerosol Separator has been developed to clean the exhaust air from finely distributed air-borne solid particles or liquid droplets. These aerosols are released during most diverse processes, such as cooking or metal processing.

The heart of all REVEN® Ventilation Systems

The X-CYCLONE® Separator

The benefits of the X-CYCLONE® System at a glance:

- Separating rate of up to 99.999 %

- Maintenance-free and self-cleaning

- Flame-arresting in accordance with DIN 18869-5 and DIN EN 16282-6

- Made of corrosion-resistant materials

- No disposable products

Coming with a lifetime warranty

Rentschler REVEN was awarded the Innovation Prize of Baden-Württemberg for the X-CYCLONE® Technology.

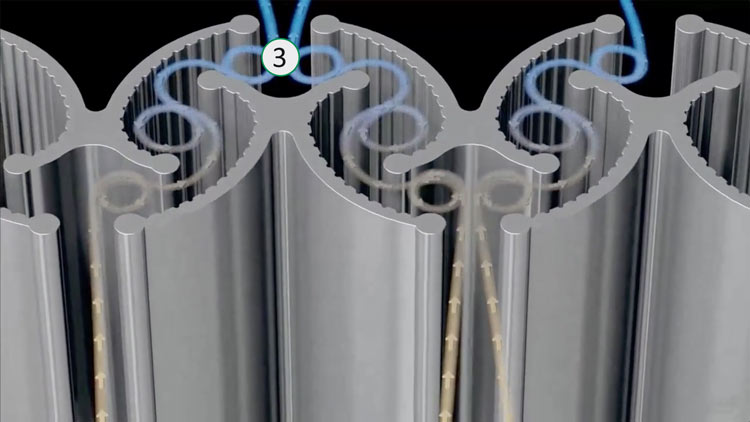

Separation of aerosols in four stages

Functional descriptioin of the X-CYCLONE® Separator

STAGE 1

The exhaust air polluted with aerosols flows into the X-CYCLONE® Separator. At the inlet (1) there is a strong acceleration of the airflow, which leads to a first separation.

STAGE 2

The high acceleration of the airflow makes it rotating in a vortex (2), which separates airborne aerosols.

STAGE 3

At the air outlet (3) of the X-CYCLONE® Aerosol Separator, the vortices collide with flowing air, thereby causing agglomeration and further separation of small aerosol particles.

STAGE 4

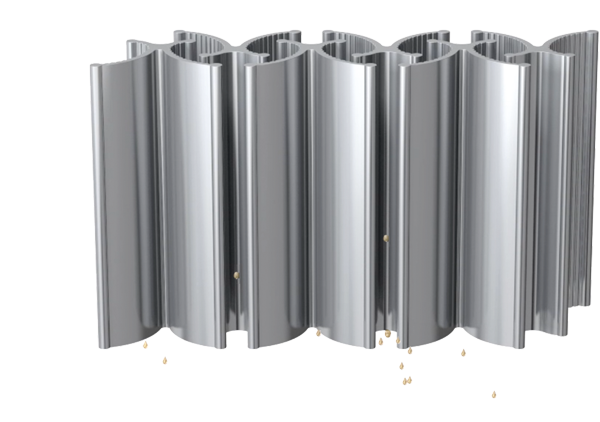

The aerosols separated in the X-CYCLONE® Aerosol Separator attach to the profile surface and run down to the bottom of the separator element as fluid mass (4).

VIDEO

Watch the four-stage separation process in the video.

Our X-CYCLONE® Separator is protected by patent rights and award-winning.

The patented heart peace of almost all REVEN products captures aerosols, oil vapours and emulsion mists with separating rates of up to 99.999 % and comes with a lifetime warranty.