Inhaltsverzeichnis

- 1. what distinguishes sustainable commercial kitchen ventilation from old systems

- 2. why cleaning and disinfection are decisive for future viability

- 3. fully automatic cleaning: a core element of future-proof commercial kitchen ventilation

- 4. digital, demand-based control: making kitchen ventilation truly intelligent

- 5. efficiency: how sustainable commercial kitchen ventilation saves energy and costs

- 6 Further components of sustainable commercial kitchen ventilation

- 7 Why planning and advice are so important

- 8 Conclusion: Future-proof commercial kitchen ventilation is automatic, digital and economical

- 9. delve deeper now: Watch the webinar video on sustainable commercial kitchen ventilation

- Follow us on social media

Future-proof commercial kitchen ventilation: how modern kitchen ventilation becomes intelligent, sustainable and safe! The requirements for future-proof commercial kitchen ventilation are constantly increasing. Today, it is no longer just a matter of extracting cooking vapors and exchanging air.

Kitchen operators are under pressure because:

- there is a lack of specialist staff,

- operating costs increase,

- Hygiene and safety are subject to ever stricter controls,

- and at the same time everything should be sustainable and efficient.

That’s why a modern kitchen needs intelligent, automated and future-proof commercial kitchen ventilation. In our live webinar, which you can now watch as a video, we show you exactly that in detail:

👉 YouTube webinar video “The future of commercial kitchen ventilation”:

In the following blog article, we summarize the most important points from the webinar and make you want to watch the full video.

1. what distinguishes sustainable commercial kitchen ventilation from old systems

Many kitchens still work with conventional, old-fashioned kitchen ventilation systems. These systems usually have:

- simple exhaust air hoods or ventilation ceilings,

- simple metal filters or grease filters,

- a fixed air volume that always runs the same,

- and almost no digital technology.

Such a system simply extracts the same amount of air everywhere, regardless of whether someone is cooking or not. It seems simple at first, but it is neither intelligent nor sustainable:

- The ventilation system often runs far too strongly.

- It also vacuums where no one is cooking.

- This wastes energy and money.

- And it produces a lot of cleaning and maintenance work.

Sustainable commercial kitchen ventilation works differently. It thinks for itself, it responds to real needs and it significantly reduces the workload for staff.

In the webinar video, we explain step by step which differences really count.

2. why cleaning and disinfection are decisive for future viability

A key point in the webinar is the cleaning and disinfection of the aerosol separators, i.e. the kitchen filters. This is where grease, oil and dirt quickly collect during operation.

As soon as a visible thin film of grease forms on the separators, guidelines such as VDI 2052 Sheet 2 require cleaning. And this is not a minor issue, but a huge effort.

2.1. Daily manual cleaning is often no longer practicable

This is the reality in many kitchens:

- The kitchen runs many hours a day.

- The separators are visibly contaminated after just one day.

- The filters often have to be removed daily, put in the dishwasher, hot-cleaned and disinfected.

In small hoods with perhaps four or five separators, this is still somehow feasible. But in modern commercial kitchens, there are often ventilation ceilings with 50, 100 or even 150 separators hanging at a height of 3 to 3.5 meters.

Then cleaning becomes a brutal, almost insane effort:

- Staff often have to work with ladders or scaffolding on a daily basis.

- There is a high risk of accidents.

- The daily routine takes a lot of time and energy.

And yet many planners pay far too little attention to this issue in the early project phases. This results in systems that work technically, but are almost impossible to manage on a day-to-day basis.

Sustainable commercial kitchen ventilation must not look like this!

3. fully automatic cleaning: a core element of future-proof commercial kitchen ventilation

Fully automated cleaning and disinfection systems are needed to reduce the huge amount of work involved.

3.1. How automatic cleaning works in the kitchen ventilation system

In modern systems, the aerosol separators are permanently installed in the hood or ventilation ceiling. They are no longer removed daily, but are automatically cleaned directly in the system.

The principle:

- The separators remain in place.

- An integrated system sprays hot water and detergent.

- The separators are flushed from the front and rear.

- The areas behind the exhaust air chamber are also cleaned.

- This removes both grease and germs.

The important thing is:

A future-proof commercial kitchen ventilation system must clean both sides. Flushing only the front is not enough for real disinfection.

This is a critical point, especially in hospital kitchens, retirement homes or large utility companies.

In the webinar, we show examples from large hospital kitchens in which over 100 separators are installed. Manual cleaning would be practically impossible there. Thanks to automatic cleaning, the system still remains hygienic and economical.

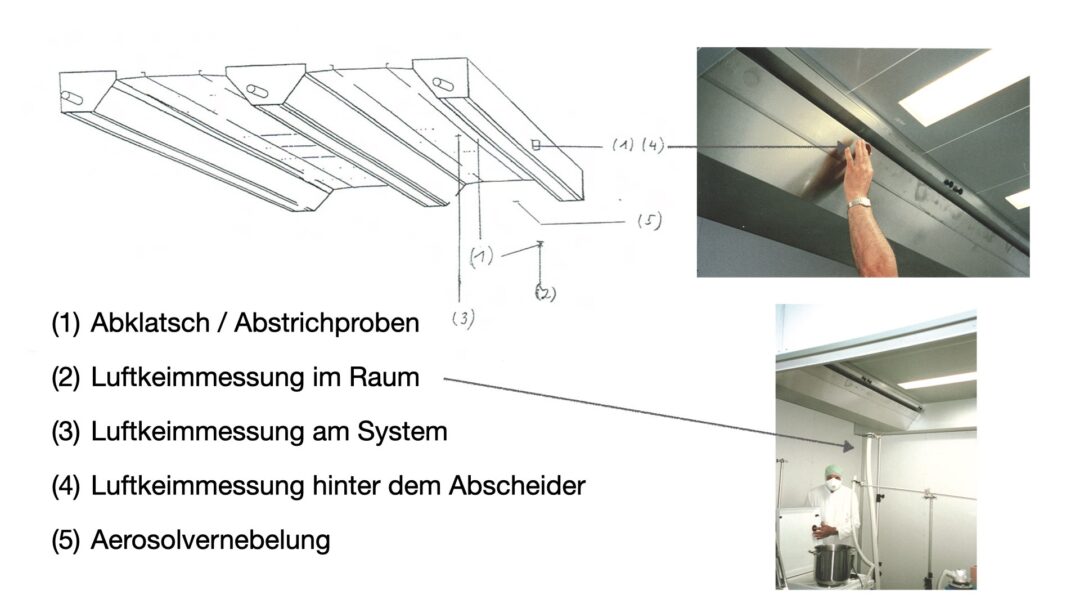

3.2. Hygiene, germs and real disinfection

In the webinar, we also talk about the fact that it’s not just about visible fat, but also about invisible germs.

- Bacteria were specifically designed in serious expert reports,

- the systems were operated,

- and then checked whether the germs had been killed.

And it shows:

- Only thorough cleaning from both sides

- with suitable water temperature

- and suitable cleaning agent

can reliably stop the growth of certain germs!

This is another reason why a future-proof commercial kitchen ventilation system without sophisticated automatic cleaning is almost inconceivable today.

3.3. Further information & download hygiene reports

The results of the hygiene report are impressive: the REVEX system can effectively eliminate germs under the test conditions. The airborne germ measurements and swab samples showed that the system enables fumes and vapors to be captured perfectly and that contamination only occurred in exceptional cases. Download the report here:

A further download describes all the components and interfaces of a modern, future-proof kitchen ventilation system with fully automatic REVEX filter cleaning:

4. digital, demand-based control: making kitchen ventilation truly intelligent

The second major topic in the webinar is digitalization. The aim here is to ensure that a future-proof commercial kitchen ventilation system does not simply “always run at the same speed”, but responds to actual demand.

4.1. The problem of the classic exhaust air ceiling

It looks like this in many kitchens:

- The planner calculates an exhaust air volume, for example 10,000 m³/h.

- It then reduces this volume with a “simultaneity factor” to perhaps 7,000 m³/h.

- These 7,000 m³/h are distributed evenly across all filter elements.

The system then extracts the same amount of air everywhere, all the time and all day long.

But in reality:

- all cooking zones are never active at the same time,

- thermals are only generated on certain devices,

- and often part of the kitchen is idle.

Nevertheless, the conventional system also draws in air where nobody is cooking. This means that valuable, air-conditioned room air is lost. This is expensive and not sustainable.

4.2. How sensors make sustainable commercial kitchen ventilation possible

A future-proof commercial kitchen ventilation system therefore works according to demand. It first detects the real demand and then intelligently regulates the air volume.

This is done using smart sensors that:

- Temperature,

- Humidity

- and thus steam development and cooking activity

very quickly. These modern and intelligent sensors:

- sit directly in the ventilation ceiling or kitchen hood,

- react within seconds,

- are resistant to grease and steam,

- and can even be cleaned in the dishwasher if necessary.

They provide the signal that the control system needs. And the control system then controls the volume flow controller and dampers in such a way that:

- more air is extracted in “active zones” (where cooking takes place),

- the air volume is greatly reduced in “passive zones”,

- and the overall system remains pressure-stable and efficient.

The result is an intelligent, future-proof commercial kitchen ventilation system that really thinks for itself.

We have compiled further information on our intelligent demand-based control systems for you in a planner PDF here:

5. efficiency: how sustainable commercial kitchen ventilation saves energy and costs

Demand-based control is not only technically exciting, but also economically very important. Because:

- Every volume of air extracted has been expensively conditioned beforehand.

- The air was heated or cooled.

- And it is then simply blown outside in conventional exhaust air kitchen hoods and ventilation ceilings.

If the ventilation is constantly running at full throttle, the temperature rises:

- the energy costs of the ventilation units,

- the heating or cooling costs,

- and also the wear and tear on the systems.

Through sustainable commercial kitchen ventilation with demand-based control:

- the ventilation only runs as much as is really necessary,

- the air volume is significantly reduced during quiet periods in the kitchen,

- and overall energy costs fall.

In the webinar, we show how this can be illustrated with a profitability analysis. This includes, for example:

- Investment costs of the technology,

- Running times of the kitchen,

- Energy prices,

- and the savings achieved through demand-controlled air volumes.

This consideration often pays off very quickly, especially for systems with many operating hours.

Link to the RECOMAX calculation app and profitability calculation:

6 Further components of sustainable commercial kitchen ventilation

In the webinar, we also touch on other topics that round off a future-proof commercial kitchen ventilation system. These include, for example:

- Induction systems in the hood,

which improve the capture of vapors. - Intelligent LED lighting,

which can be dimmed when no one is working in the area. - Fixed fire extinguishing systems,

that raise safety and fire protection to a new level. - Sophisticated interface planning,

so that ventilation, control, fire protection, water, waste water and building management systems work together seamlessly.

All these components help to ensure that the kitchen can be operated safely, efficiently and conveniently not only today, but also for many years to come.

7 Why planning and advice are so important

Sustainable commercial kitchen ventilation is not created by chance. It is created when planners, operators and manufacturers work together at an early stage and ask important questions in good time:

- How often does the kitchen really run?

- How high is the hygiene requirement?

- How do the staff manage the cleaning workload in the long term?

- Which digital functions should be integrated?

- Which interfaces does the system need?

In the webinar, we will show concrete examples from practice in which precisely these questions have led to good solutions, but also cases in which these issues were considered too late and therefore have to live with massive problems today.

8 Conclusion: Future-proof commercial kitchen ventilation is automatic, digital and economical

Let us summarize:

Sustainable commercial kitchen ventilation…

- reduces the cleaning effort through fully automatic cleaning and disinfection of the aerosol separators,

- protects staff and operators because it avoids dangerous climbing and manual work on hard-to-reach kitchen filters,

- works digitally and according to demand, because sensors detect the actual cooking activity and distribute the air volume intelligently,

- saves energy and costs because it does not extract the same amount of air all day long,

- and forms a platform for further intelligent functions such as induction, LED control, fire extinguishing technology and smart interfaces.

This is exactly the kind of system that will exist in the future. Simple, rigid exhaust hoods without intelligent technology will have an increasingly difficult time because they are neither sustainable nor economical.

9. delve deeper now: Watch the webinar video on sustainable commercial kitchen ventilation

This blog article gives you a comprehensive overview. But in the webinar video, we go into more detail, showing images, animations and real examples from projects. If you:

- are planning to build a new kitchen,

- want to renovate an existing system,

- or simply want to understand what sustainable commercial kitchen ventilation looks like in practice,

then watch the recording now:

👉 Webinar video “The future of commercial kitchen ventilation”

There you can see:

- Pictures from real kitchens,

- Examples of automatic cleaning,

- Sensors and control in use,

- as well as references to further planning aids and guides.