Inhaltsverzeichnis

- Extraction alone is not enough for efficient commercial kitchen ventilation!

- Commercial kitchen ventilation serve to protect the white brigade at work. For this purpose, an extractor hood or a ventilation ceiling with grease traps is installed above the stove block. One particularly efficient extraction technology is based on induction ventilation.

- Very complex flow conditions in a commercial kitchen ventilation system

- The function of efficient commercial kitchen ventilation:

- The new induction principle for modern commercial kitchen ventilation

- The induction nozzle was optimized using CFD

- Ideal for narrow kitchens

- Examples of commercial kitchen ventilation in practice

- Show kitchen in Hesse

- Kitchen hoods with the new induction technology also in the MEIKO training building

- REVEN commercial kitchen ventilation high above the clouds

- Delivered just in time

- Also induction ventilated ceilings

- Best practice examples for condensate-tight elements

- Low budget solution

- Large ventilated ceiling also with induction system

- Mixture of kitchen ventilated ceiling and kitchen hood

- Summary as explanatory video

- Attachments:

Extraction alone is not enough for efficient commercial kitchen ventilation!

Commercial kitchen ventilation serve to protect the white brigade at work. For this purpose, an extractor hood or a ventilation ceiling with grease traps is installed above the stove block. One particularly efficient extraction technology is based on induction ventilation.

To prevent the cooking brigade from standing in a fog, the commercial kitchen ventilation system must extract and filter the greasy fumes. Of course, this only works efficiently if an important function is fulfilled first – the complete capture of the fumes and the pollutants they contain. And this is the crux of the matter: Most extractor hoods and exhaust air ceilings cannot do this.

Capturing – as the experts call the capture of cooking fumes – is the first task of a commercial kitchen ventilation system. After all, what use is a high degree of separation of the grease traps if only two thirds of the vapor volume reaches the exhaust air duct, while one third circulates in the dead zone of the hood or flows back into the kitchen.

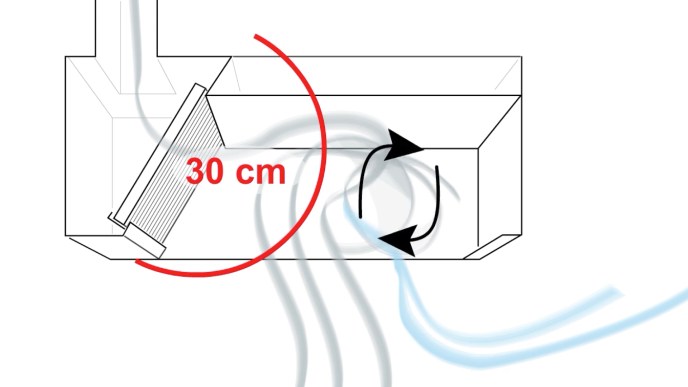

The latest studies using CFD numerical flow simulation reveal that such dead zones and air leakage occur in most kitchen hoods. The reason for this is that the suction of the air is only effective up to a distance of 30 cm from the separator (Fig. 1). Further away, the vapors circulate uncontrollably in the hood space and leave it partially, even if the kitchen hood overhangs correctly. The required air hygiene in the kitchen is therefore not guaranteed.

Very complex flow conditions in a commercial kitchen ventilation system

The Swabian hood and ceiling manufacturer Rentschler Reven has meticulously examined the flow conditions in many commercial kitchens and has come to the conclusion that the flow conditions in the kitchen hood are very complex. Much more complicated than the VDI guideline 2052 describes. The result of the CFD flow simulation: suction alone is not enough. Additional impulses are necessary in order to ensure complete capture of the air. With the help of the CFD software mentioned above (see Appendix 1), a new flow principle for commercial kitchen ventilation was developed under the name of induction technology. It was initially discussed controversially in specialist circles.

The function of efficient commercial kitchen ventilation:

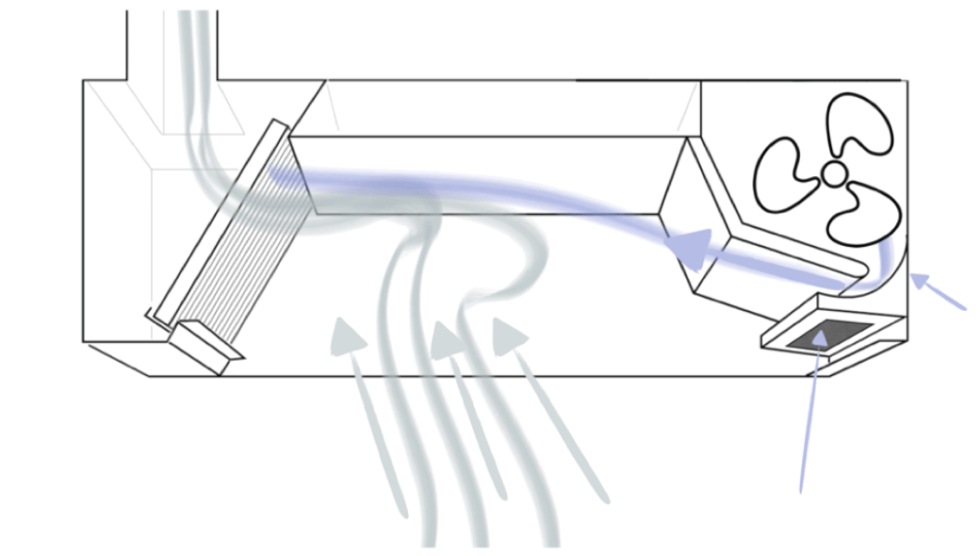

A supporting jet is blown horizontally into the kitchen hood (Fig. 2). This draws in (induces) the rising vapor from below. The air volume required for this is taken from the room air at the front edge of the kitchen hood (Fig. 3). At around 20-25°C, the temperature of the supporting jet is well below the vapor temperature of around 80°C. Consequently, condensation of the cooking vapors takes place in the separator and not in the exhaust air duct. This keeps the duct dry and germ-free and increases preventive fire protection.

As there are no longer any dead zones in the new kitchen hoods, the cooking vapors are captured completely and driven to the separators. An infinitely variable fan allows for smooth operation between 0 and 100%. This means that there are no draughts in the area where the chefs are working, even when the kitchen is in full operation.

The new induction principle for modern commercial kitchen ventilation

Reven did not invent the induction principle. Tens of thousands of kitchen hoods are in use in the USA. They are typical “hoods light”, i.e. crudely cobbled together metal boxes with insufficient effect and a high noise level. The first induction hoods in Germany also had their teething troubles and often did not achieve the desired effect: cold outside air was blown in for the support jet; this required an additional supply air device. The additional cost compared to conventional hoods was considerable. Specialist planners were therefore often critical of the principle.

The induction nozzle was optimized using CFD

With Swabian thoroughness, Reven has, however, upgraded the principle to European standards via CFD and brought it onto the market as a premium product. In practice, it is important that a clean flow leaves the induction nozzle in the direction of the separator.

The most important component is therefore the induction nozzle. Reven has optimized it in terms of flow technology and had it internationally protected by a patent (Fig. 4). The design improvements, above all the elimination of the introduction of cold outside air, have reduced the price difference to zero compared to previous kitchen hoods with induction. Induction technology has thus become a success story, as evidenced by the many reference installations.

Ideal for narrow kitchens

Commercial kitchen ventilation reveals its true strength in narrow kitchens with a high power density. Here, large volumes of air have to be introduced without draughts and with low noise levels, and catering kitchens are becoming smaller and smaller because the tipper, kettle, stove and deep fryer are often combined into one cooking block. And space costs are becoming increasingly expensive.

The use of convenience food also contributes to the downsizing of kitchens. In the near future, 3D food printing will be added to this. For example, 100 kW connected load in a 20m2 kitchen is not uncommon. In the catering sector, however, there are production kitchens that prepare 1,000 (!) meals a day on 15m2. However, vapors, fumes and heat must be kept out – and draught-free, so that the cooks don’t catch a cold. This is a challenge for the ventilation engineer. With induction technology, the specialist planner has the right solution at hand.

Examples of commercial kitchen ventilation in practice

“Herrenküferei” in Markgröningen, Swabia, is a 600-year-old, plastered half-timbered house that houses a hotel and restaurant. Old hotel kitchen was recently renovated at great technical expense. Listed building required a great deal of imagination and technical finesse on the part of the ventilation engineer, as many of the walls are crooked and not at right angles. Furthermore, the preservation order not only prohibits changes to the façade, but also to the stud framework and beams inside.

The narrow kitchen has a low ceiling height and is packed with appliances. It measures around 80m2 and the air volume calculation resulted in a supply air volume of around 10,000m3/h with full cooking operation. How can the high supply air volume be achieved without pulling the chefs’ hats off their heads? Rentschler Reven solved the problem with several customized kitchen hoods with induction made of stainless steel (Fig. 5).

Show kitchen in Hesse

A three-storey residential building with the restaurant “Da Antonio” on the first floor was recently built in Kelkheim, Hesse. The “glass” kitchen measures around 30m2 and offers Indian and Italian specialties. Guests can watch the food being prepared. Pizza ovens, combi-steamers, gas woks and powerful tandoori ovens create a high power density in a small space. Planners and client opted for a commercial kitchen ventilation system based on Reven’s induction principle. Customized kitchen hood was installed by the Mainz-based TGA company Dornhöfer.

The high heat and humidity loads in Kelkheim made a high air exchange rate necessary. However, only 3,000m3 of the supply air volume of 5,000m3/h flows through the cooking zone, with the remainder effectively extracting the vapors as an induction flow. This ensures the required air hygiene without draughts. As the supply air volume to be preheated is less than 4,000 m3/h, it was possible to dispense with the heat recovery required by the EnEV.

Kitchen hoods with the new induction technology also in the MEIKO training building

Meiko also favors the induction solution. The leading dishwasher manufacturer in Offenburg/Baden recently moved into a new training building with two conveyor dishwashers. Among other things, different operating conditions and load cases are simulated for the new generation of kitchen staff.

The client chose four induction kitchen hoods of the latest generation from Reven to ventilate the scullery. The stainless steel hoods each have an air flow rate of 2,000m3/h and were installed by Büchele Lufttechnik from Karlsruhe. (Fig. 6). They condition the kitchen without draughts.

Last but not least: Chinese smartphone manufacturer Huawei has its European headquarters in the Globalworth Tower in Bucharest (Fig. 7). The central kitchen and canteen are located on the 25th floor of the 120 m high office building. In the kitchen, the large woks with a diameter of approx. 1 m alone cause a lot of vapor formation as well as high heat and moisture loads. The commercial kitchen ventilation system went into operation when the building was completed in 2015. It proved to be inefficient and left the cooking brigade standing in fumes and draughts. Replacement was urgently needed.

REVEN commercial kitchen ventilation high above the clouds

When designing the new system, the changing pressure conditions (wind pressure) at a height of approx. 70 m had to be taken into account. Furthermore, contamination of the façade by greasy exhaust air had to be avoided at all costs. Reven agreed a system concept with several induction hoods and an aluminum ventilation ceiling with the client. Integrated are X-Cyclone grease separators, LED lights and a UV system to remove odors from the exhaust air. Total exhaust air volume: 30,000m3/h. The ventilation system was installed within 4 weeks as part of the overall renovation of the kitchen.

All kitchen hoods with induction are equipped with highly effective X-Cyclone grease separators, which have a constant degree of separation that does not break down when ventilation is throttled (Fig. 8 and Appendix 2).

Delivered just in time

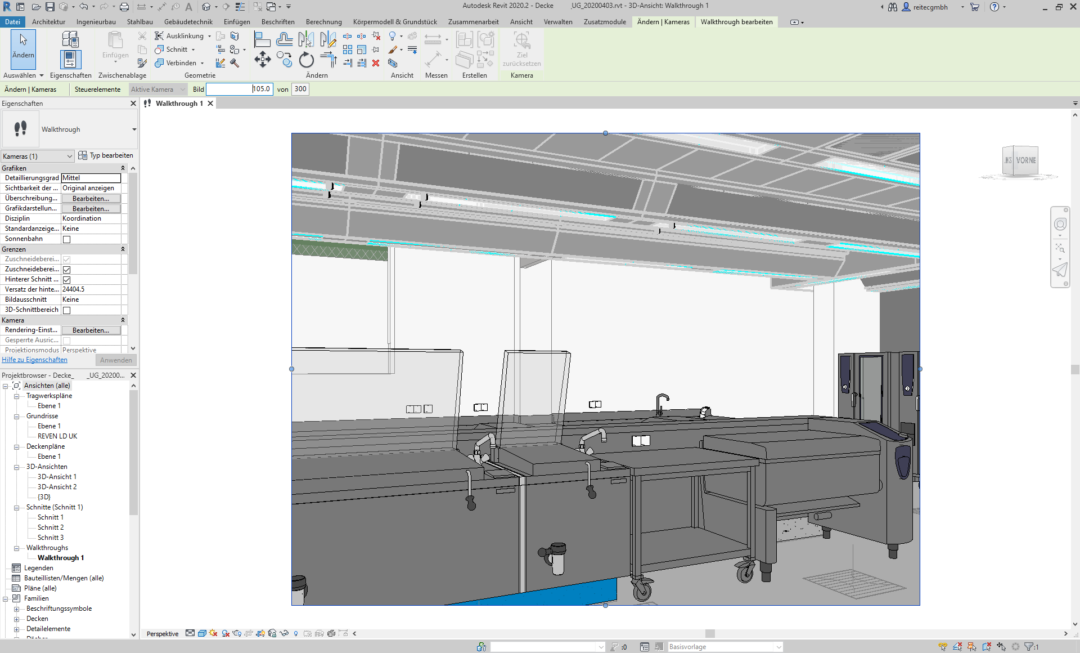

Reven uses state-of-the-art planning methods when designing induction ventilation: The system is designed virtually on screen using the BIM method (Fig. 9). BIM (Building Information Modeling) is currently the most advanced working method for planning and executing a system. All those involved in the construction are networked and can find out about the current status of the building and any changes at any time (see Appendix 3).

The components of the kitchen hoods are prefabricated in the factory with millimeter precision (Fig. 10) and shipped to the construction site just in time. This saves the client expensive wage hours on site and the installation company achieves a higher hourly turnover per man. This also ensures cost and schedule reliability. In the case of retrofitting, installation is sometimes carried out without interrupting kitchen operations. The chefs work during the day and the ventilation fitters come in at night.

A few remarks on the introduction of the supply air. It is introduced from above through low-pulse, laminar displacement outlets and seeps almost vertically down to the floor (Fig. 11). It thus supplies the occupied zone with fresh outside air without draughts (so-called stratified flow). The ceiling remains clean because no greasy air is whirled up in the kitchen. In contrast, according to Reven, horizontal blowing has not proved successful because the horizontal supply air flow can deflect the rising thermal air flow. If the supply air is blown in horizontally, the minimum distances to the extraction points recommended by the manufacturer must always be observed.

Also induction ventilated ceilings

The positive experience with induction hoods prompted Reven to also equip ventilation ceilings with induction technology. The ceiling spans the entire room; its smooth, condensate-tight welded surfaces can be cleaned with a steam jet and the aerosol separators can be moved if the kitchen is extended or reorganized (Fig. 12). Changes to the layout of the kitchen are therefore unproblematic from an air technology point of view. Like the hood, the induction ceiling is free of dead space so that the vapors are completely captured.

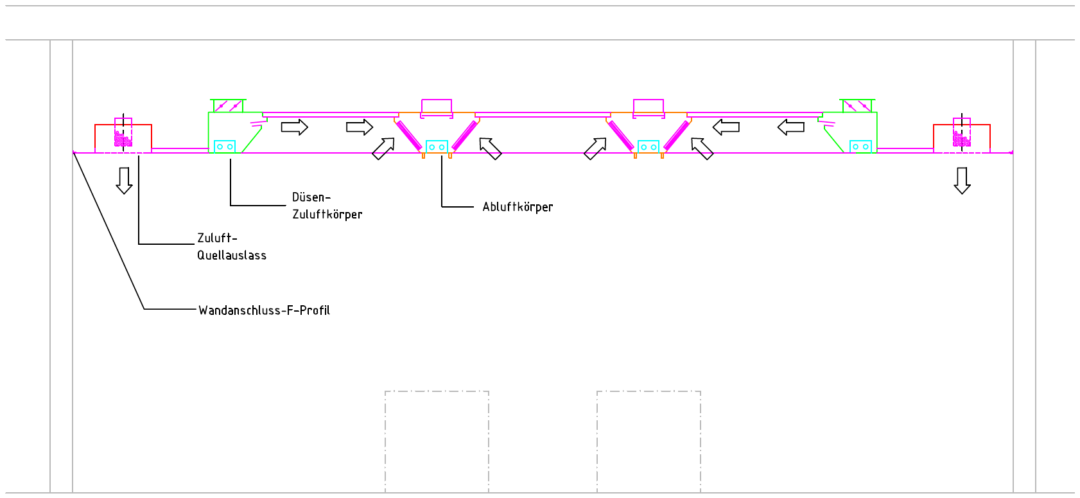

Exhaust air leaves the room through linear suspended exhaust air modules. Aerosol separators are installed in these. The slot-shaped induction modules are suspended opposite them (Fig. 13).

Exhaust air modules and the exhaust air chamber behind them form a closed, condensate-tight welded construction. As a result, the exhaust air does not come into contact with the building. Due to the many aggressive cleaning agents and the threat of pitting, the supply and exhaust air modules are preferably made of stainless steel. This “closed commercial kitchen ventilation” saves the building owner from having to periodically clean the ceiling cavity and prevents sooting of the masonry due to fatty acids. This also improves structural fire protection.

Best practice examples for condensate-tight elements

Exhaust air modules and the exhaust air chamber behind them form a closed, condensate-tight welded construction. As a result, the exhaust air does not come into contact with the building. Due to the many aggressive cleaning agents and the threat of pitting, the supply and exhaust air modules are preferably made of stainless steel. This “closed air duct” saves the building owner from having to clean the ceiling cavity periodically and prevents sooting of the masonry due to fatty acids. This also improves structural fire protection. Here are some examples of best practice:

The 80 m high Main-Forum in Frankfurt/Main is a mixed residential and office building. Among other things, it houses the headquarters of IG Metall. The central kitchen of the building, which was erected in 2003, was equipped with a conventional canteen kitchen ventilation system, which caused considerable energy costs. It was recently demolished and replaced by a modern induction ceiling made of V2A stainless steel with a surface area of 60m2 and an exhaust air volume of 11,000m3/h.

A 200 m² induction ceiling made of stainless steel and powder-coated aluminum was recently installed in the kitchen of the Bundeswehr hospital in Ulm.

Low budget solution

Another case: In Frankfurt/Main, Caritas operates a new catering kitchen for the homeless. Due to the tight budget, the administration opted for the cheapest supplier’s extractor hood. The complaints from the cooking brigade were not long in coming: the draughts were unacceptable and the kitchen could not be kept at a comfortable temperature.

In addition, condensation was dripping into the soup at the low speed setting. After the first winter, the kitchen hood was replaced with an induction ventilation ceiling. The company RUF Gebäudetechnik from Kleinheubach installed the white-coated ceiling, designed for an exhaust air volume of 5,400m3/h. Since then, the staff have been very satisfied with the air conditions. Since then, the staff have been very satisfied with the air conditions and no longer risk catching a cold.

Large ventilated ceiling also with induction system

A 200 m² induction ceiling made of stainless steel and powder-coated aluminum was recently installed in the kitchen of the Bundeswehr hospital in Ulm.

Reven realized a gigantic project at Frankenberg Food in Würselen near Aachen. The family-run company produces high-quality frozen meals for international airlines (in-flight meals) and other large-scale consumers. The ventilation ceiling with induction modules made of chrome-nickel steel measures around 1,000 m² and is designed for a total air flow rate of 80,000 m³/h (Fig. 15).

To save energy, the air volume is controlled depending on the vapor; humidity and heat sensors measure the vapor density and automatically control the fan speeds. Each cooking zone has its own sensor system for air volume control. This saves energy, extends the service life of the grease separators and prevents draughts.

The Frankenberg ceiling is probably the largest induction ventilation ceiling that has ever been realized and is one of the most complex projects in Reven’s company history. The company used 12 tons (!) of stainless steel alone for the ceiling in Würselen.

Meanwhile, hybrid ceilings – a combination of exhaust air and/or induction hoods and flat ceilings – are becoming increasingly popular with planners and interior designers. Its advantages: Flat design is also suitable for rooms as low as around 2.50 m in height. Displacement outlets for the supply air are integrated. Supply air trickles into the room without draughts and with little impulse. Hybrid ceilings are designed solely by the parent company Reven.

Mixture of kitchen ventilated ceiling and kitchen hood

The elegant design of the hybrid ceiling enhances the look of the kitchen. The ceiling is easy to clean; there are no visually distracting inspection openings because the ceiling can be easily opened at any point. It is water-repellent, flame-retardant and complies with hygiene guidelines, and is supplied from a single source, including installation and cabling of the LED lights. This creates planning security and eliminates the recurring interface problems with other trades.

In Frankfurt/Main, the new restaurant in the basement of the trade fair tower was fitted with a 100m2 stainless steel hybrid ceiling, designed for an exhaust air volume of 15,000m3/h.

The ceiling solution pays off for rooms from 50-60 m²; below this, the extractor hood or the aforementioned hybrid ceiling is the favorite. Induction technology is also increasingly being used in the food and pharmaceutical industries to comply with hygiene regulations in production. Digital interfaces allow integration into a building management system. Reven induction technology is therefore ready for the kitchen and Production 4.0.

Summary as explanatory video

Attachments:

Appendix 1 Explanation of terms: CFD flow simulation

CFD (Computanional Fluid Dynamics) is an imaging method for simulating complex air flows. It supplements empirical tests in the flow laboratory. Aircraft and racing car designers, for example, use it to optimize wings and spoilers. Rentschler Reven uses the CFD method to realistically depict particle paths for grease separation in commercial kitchens.

This is because not all particle sizes are separated equally well; they move on their own paths and do not necessarily follow the air flow. It turned out, for example, that 3-5 µm pollutant aerosols move along different paths than 0.1 µm particles due to their inertia. They are relatively easy to intercept – in contrast to 3-5 µm particles, which require an agglomerator to combine (agglomerate) the small particles into larger droplets.

The CFD software can be used on a standard PC to optimize the geometry of air technology components, for example turbulence-causing components and trailing edges, as well as the optimization of displacement and induction outlets.

The advantage of CFD over experimental methods in the laboratory is that the measured values are not only determined at certain points, but all physical variables are recorded and displayed at once. CFD is therefore a cost-effective alternative to smoke tests and endless wind tunnel tests.

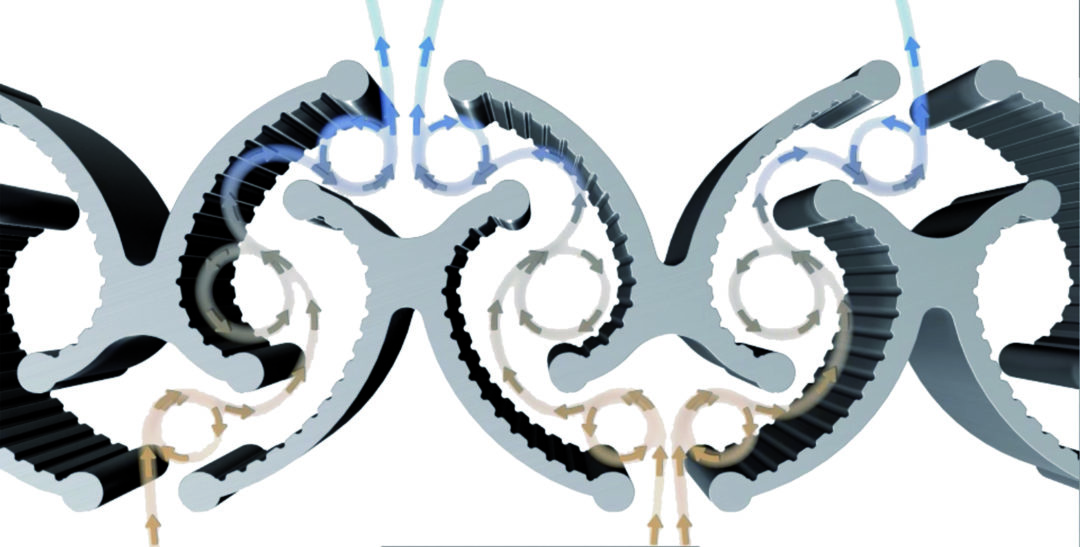

Appendix 2 Explanation of terms: X-Cyclone grease separator

Patented X-Cyclone separators do not store the grease in a filter medium but eject it through repeated air deflection. Exhaust air flow is set in rapid rotation in the cyclone separator elements. Centrifugal forces remove even micro-fine aerosols almost completely. Flow off along the stainless steel blades into a collecting channel. Separator practically cleans itself.

This stabilizes the separation process – in contrast to the air filter, whose efficiency decreases with increasing saturation and drives up fan costs due to the higher air resistance. If maintenance is neglected, the filter medium can become clogged and detachment can occur on the clean air side. This can also transmit viruses that adhere to the aerosols and dust particles. Regular filter changes are essential. X-Cyclone separators, on the other hand, have a service life of up to one year and are cleaned with a steam jet.

Appendix 3 Explanation of terms: Holistic planning with BIM

Building Information Modeling, or BIM for short, is a holistic working method for the planning, execution and management of a building. Everyone involved in the construction process is networked and can find out about the current status of the property and any changes at any time. Experts also speak of construction site optimization. Planning errors and collisions between trades are avoided and reworking is minimized.

Rentschler Reven is one of the first HVAC contractors to plan and implement its projects using the BIM method. The manufacturer of commercial kitchen ventilation systems designs the system using CAD and then displays the project as a 3D model. The viewer can enter the kitchen virtually and view it from all perspectives.

Market researchers from BauinfoConsult found that around 60% of architects used BIM in 2019, while MEP companies are still hesitant. One of the reasons for this is that the trades have not yet been able to agree on uniform standards. Reven is supporting the trend by providing architects and specialist planners with technical data sets for its products.