Inhaltsverzeichnis

- Why are these fluorescent tubes banned?

- What are the alternatives to fluorescent tubes?

- Don’t make any mistakes when planning lighting for commercial kitchens!

- Further information and download

- Registration for the REVEN LED webinar powered by cci-Dialog GmbH on Friday, October 13, 2023

- Follow us on social media

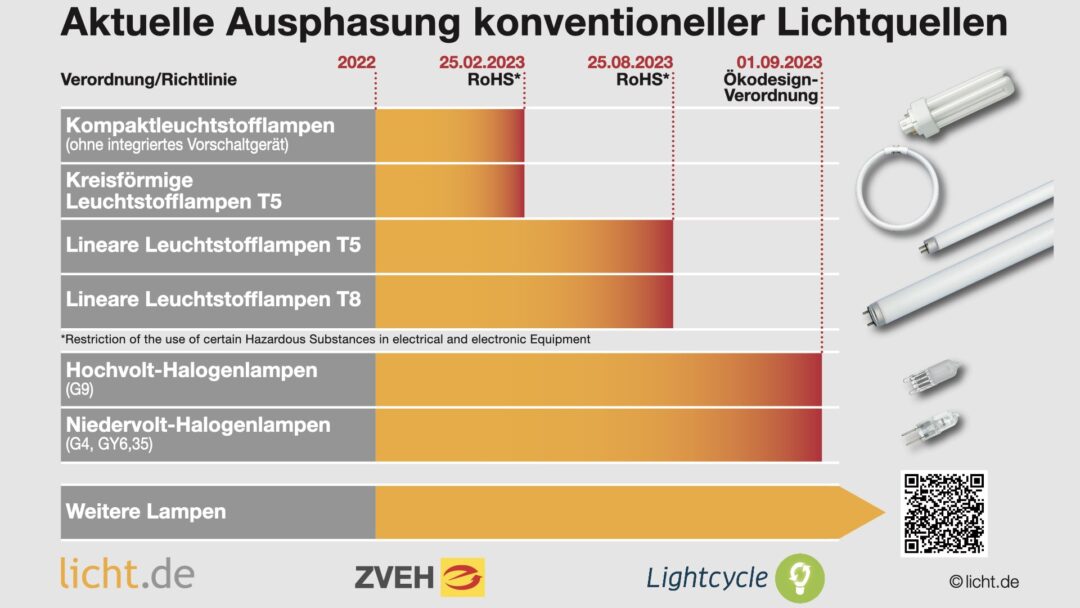

From August 25, 2023, the EU directive will ban lamps with fluorescent tubes. The ban serves to limit hazardous substances in electrical and electronic equipment (RoHS – Restriction of the use of certain Hazardous Substances in electrical and electronic Equipment). From August 25, 2023, T8 and T5 lamps may therefore no longer be sold.

The ban applies to almost every design and variant of T5 and T8 fluorescent tubes, especially those with the standard sizes of 18, 36, 58 watts or 600 mm, 1,200 mm, 1,500 mm.

Why are these fluorescent tubes banned?

Several reasons led to the ban on T5 and T8 fluorescent tubes. Many fluorescent and halogen lamps do not meet the minimum efficiency values set by the EU to achieve the climate and efficiency targets. For example, T5 and T8 fluorescent tubes have relatively poor values compared to modern LED lamps. The service life is much shorter, as is the luminous efficacy. With fluorescent tubes, only a small percentage of the electricity used is converted into light. The gas mixtures of argon and mercury vapor used in the glass tubes fall under the RoHS Directive.

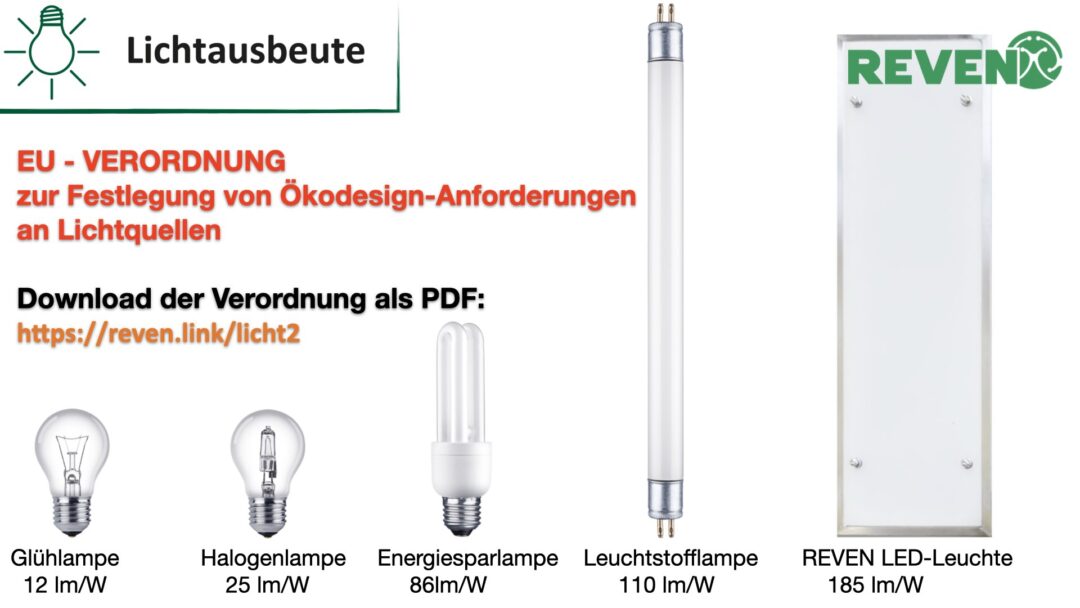

What are the alternatives to fluorescent tubes?

Modern LED lights can be a good alternative to conventional T5 and T8 fluorescent tubes. However, it should be noted that not just any LED light is always a sensible, efficient and energy-saving alternative!

Don’t make any mistakes when planning lighting for commercial kitchens!

The right lighting is always highly relevant for occupational safety in commercial kitchens! Therefore, when planning a commercial kitchen, pay attention to aspects such as brightness, contrast and color. Other important aspects to consider are

1.) Illuminance – very often too low values and assumptions are used here!

2.) Color deviation of the LEDs – far too often manufacturers use poor quality LED components, which leads to high color deviation!

3.) Uniform illumination – In commercially used rooms, uniform illumination must be ensured, as large jumps between bright and dark areas lead to major problems in terms of occupational safety. If the work areas of a kitchen look like a chessboard due to light and shadow, the lighting design and the arrangement of the luminaires are faulty!

4.) Luminous efficacy – Cheap and simple LED luminaires use poor quality LED drivers!

5.) Lamp construction – Lamp housings and lamp covers are often made of materials and seals that have no place in a commercial kitchen (wet and hygienic room!!!)!

Further information and download

The QR code in the image links to this PDF:

Registration for the REVEN LED webinar powered by cci-Dialog GmbH on Friday, October 13, 2023