Inhaltsverzeichnis

- Industrial air purification always follows the same principle

- Filtering and separation in industrial air purification are not the same thing

- Understanding aerosols means understanding air purification

- Efficiency does not come from assumptions, but from measurement

- Podcast: Filtering or separating – knowledge bundled and categorized

- Conclusion: Air purification needs understanding

- Follow us on social media

Filtering or separating? What industrial air purification really does. In industrial air purification, there is a lot of talk about air volumes, fans and energy efficiency. These topics are important because they determine how air is captured and transported. However, one central question is often pushed into the background:“How are airborne pollutants actually removed from the exhaust air flow?”

It is precisely at this point that it is decided whether industrial air purification really works or is only convincing on paper.

Industrial air purification always follows the same principle

Technically speaking, industrial air purification can always be divided into three clearly defined steps:

- Firstly, pollutants must be recorded where they are produced.

- Secondly, these pollutants must be reliably extracted with a defined air flow.

- And thirdly, they must be removed from this exhaust air flow.

While planning and design often focus intensively on the first two steps, the third step is often underestimated. Yet it is precisely this step that is crucial. Because clean air can only be produced if pollutants are reliably separated.

Filtering and separation in industrial air purification are not the same thing

In practice, filtering and separation are often equated. However, technically they are two completely different operating principles.

Filters trap pollutants in the air flow. Grease, oil or dirt particles are deposited in the filter medium. The system changes with increasing operating time. The pressure loss increases, the flow changes and efficiency can fall. At the same time, fire load builds up, especially with aerosols containing grease or oil.

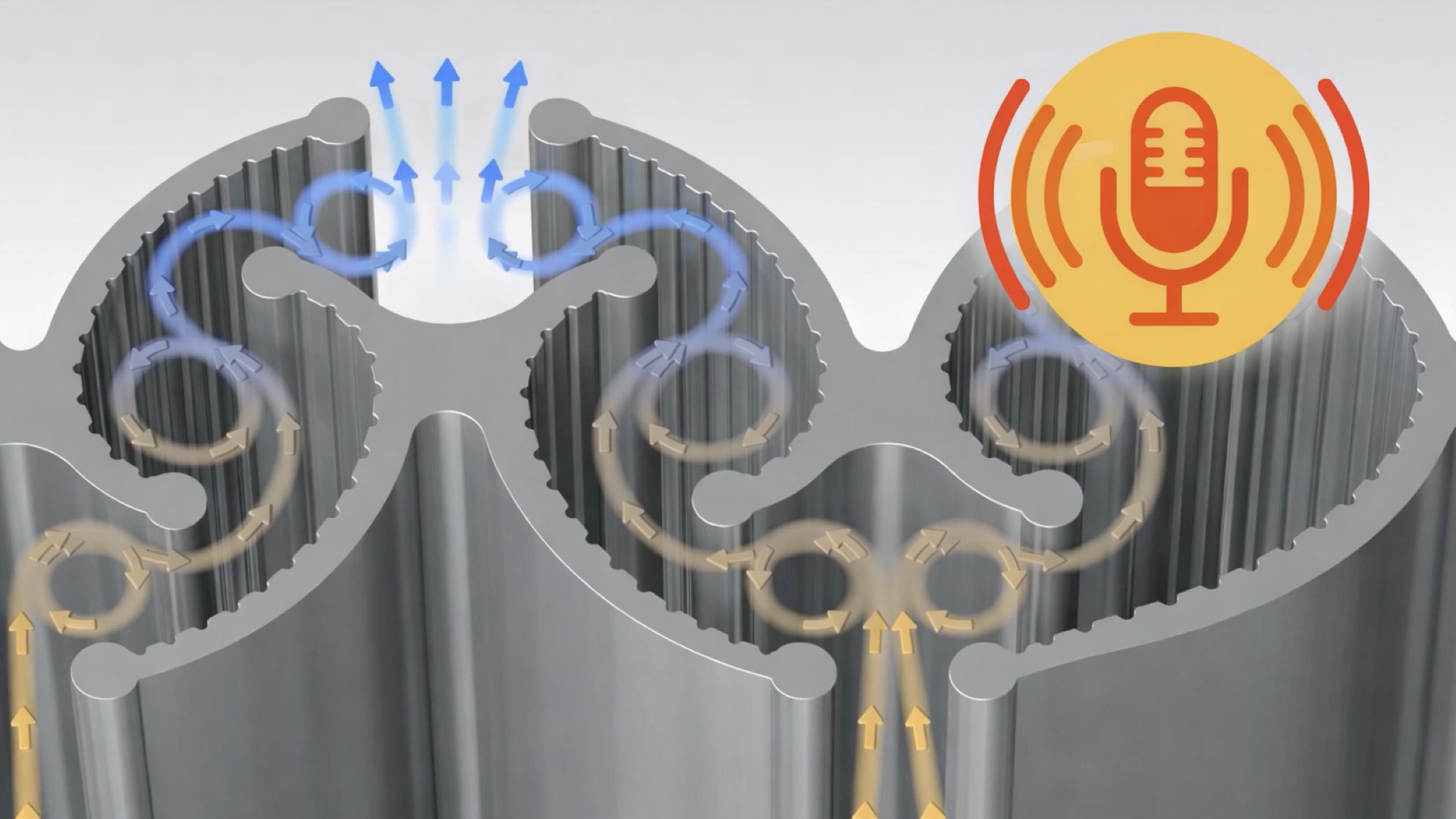

Separators take a different approach. They use physical effects to specifically separate aerosols from the air flow. The aim is not to permanently retain pollutants, but to separate them in a controlled manner. This is precisely why separators remain more stable and safer in continuous operation.

Especially in industrial applications and commercial kitchens, this difference makes all the difference.

Understanding aerosols means understanding air purification

A central misunderstanding in air pollution control concerns the term aerosol. Many people equate aerosols with vapor or smoke. But aerosols are something else.

They consist of very fine liquid or solid particles that follow the air flow very precisely. This is why they cannot simply be filtered out. If you want to remove aerosols from the air, you need to understand their behavior. This includes particle size, inertia and flow behavior.

Only if this physical understanding is available can separators be specifically developed and optimized. Without this knowledge, air purification remains pure theory.

Efficiency does not come from assumptions, but from measurement

Another critical point is the proof of effectiveness. Efficiency can neither be seen nor smelled. It is therefore not enough to rely on subjective impressions.

Measurement technology forms the basis of any serious development in industrial air purification. Because only those who measure can compare. And only those who compare can improve. This applies in particular to continuous operation, as many systems work well when new, but lose their effectiveness over time.

Without measurement technology, efficiency remains an assertion. With measurement technology, it becomes comprehensible and verifiable.

Podcast: Filtering or separating – knowledge bundled and categorized

We have taken upprecisely these connections in a new, detailed AI-supported podcast episode of Luftpost.

The episode is based on content from over 200 blog articles and around 280 YouTube videos that we have published over the past few years. With the help of AI, we have systematically bundled and structured this knowledge for the first time and transferred it into a coherent sequence of knowledge.

🎧 Click here to go directly to start the podcast episode:

Conclusion: Air purification needs understanding

Industrial air purification is more than just moving air. It is created where understanding meets technology. That is why separation, measurement technology and experience determine the quality of a system.

Anyone seriously considering the question of whether filtering or separation is the better solution cannot ignore these basic principles. This is precisely why the podcast, blog and webinar address this topic together – in a well-founded, comprehensible and practical way.

Download the X-CYCLONE high-performance separator guide here: