Inhaltsverzeichnis

- Why is air purification in production so important?

- Not only people, but also machines need protection

- Clean air possible even with complex processes

- Why not every air purifier is suitable for every machine

- How do I find the right machine tool air cleaner?

- Intelligent technology makes the difference

- It all depends on the materials

- Conclusion: clean air is not a luxury, but a duty

- Follow us on social media

Clean air in production: Why machine tools need air purifiers! In many manufacturing companies, machine tools run around the clock. They mill, grind, drill or turn metal parts – often using cooling lubricants. This produces a fine mist that not only endangers the health of employees, but can also damage machines and electronics. This is exactly where machine tool air cleaners come into play. But why are they so important? And what is important when choosing one?

Why is air purification in production so important?

When machine tools are working, aerosols – tiny droplets of oil or emulsions – are produced. These float in the air and can spread throughout the room. It becomes particularly critical when machines are open or the doors are opened during loading and unloading. Employees then breathe in these fine particles – often without realizing it.

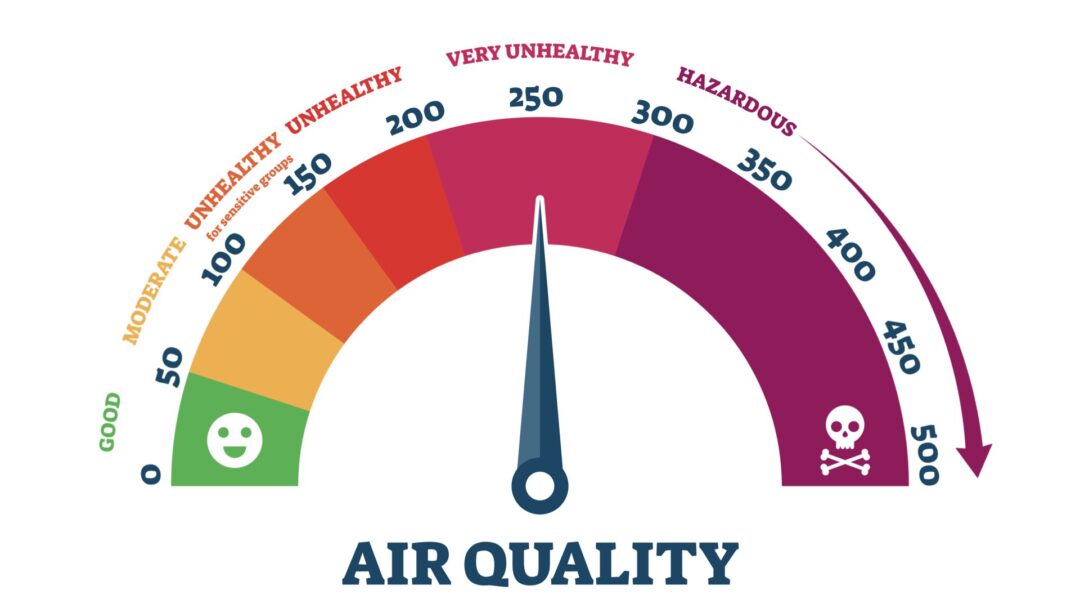

According to the World Health Organization(WHO), air with a pollutant value of 100 micrograms per cubic meter is already considered “unhealthy”. In many production halls, however, this value is far higher – in some cases over 300 micrograms! For comparison: in large cities with high levels of pollution, driving bans are threatened at such levels.

Machine tool air cleaners ensure that precisely these invisible hazards are reduced – for healthier air and greater safety in the workplace.

Not only people, but also machines need protection

In addition to protecting employees, there is another, often overlooked reason for using air purification systems: the sensitive electronics. Today, almost every modern machine contains IT – from sensors and control systems to complex automation technology. These components react sensitively to the oily mist.

If the mist settles on circuit boards, this can lead to short circuits. In extreme cases, there is even a risk of entire systems failing. It is therefore important to think not only about protecting people, but also about the technology in the room.

Clean air possible even with complex processes

Many companies fear that clean production is associated with high costs or great effort. But practice shows: Even large, heavily polluted machines can achieve almost clinically clean air quality with the right technology.

One example: Huge stainless steel pipes with millions of drill holes were produced in a paper manufacturing plant. Despite intensive processing with oil and 200 drills working simultaneously, air quality comparable to that in city parks was achieved thanks to suitable air purifiers. This was made possible by well thought-out planning, the right technology – and the right settings.

Why not every air purifier is suitable for every machine

Many people believe: “One device for everything – that’s enough.” But this is a fallacy. Depending on the machining process, cooling lubricant used (oil or emulsion), material and air volume, customized solutions are required.

A simple example: If the air cannot flow in properly, a vacuum is created. The result? The air purifier works inefficiently. Or worse: it doesn’t work at all.

It is therefore important to match the extraction technology precisely to the machine. The air purifier can only work optimally if the inflow and outflow are in balance.

How do I find the right machine tool air cleaner?

The answer: with a systematic analysis. Companies like REVEN and its partners use a detailed checklist for this purpose. It clarifies questions such as:

– What processing is carried out?

– Is oil or emulsion used?

– How large is the machining area?

– What is the cooling lubricant pressure?

– How open or closed is the machine?

With this information, the right system can be selected – and in such a way that it works precisely for the respective requirements.

You can download the checklist here:

Intelligent technology makes the difference

Modern machine tools Air purifiers no longer simply work “on the fly”. They can be controlled intelligently – for example via frequency converters that communicate with the machine control system. This allows the air cleaner to start up automatically when the machine stops or the door is opened.

Maintenance is also easier: thanks to smart technology, the system itself recognizes when a filter change is necessary and indicates this at an early stage – before faults occur.

It all depends on the materials

Another important topic: the housing material. While many manufacturers rely on painted sheet steel, REVEN takes a different approach. All devices are made of high-quality, rust-free stainless steel – not for visual reasons, but because many cooling lubricants attack even the strongest coatings in the long term. Stainless steel is simply more robust and durable – especially in demanding environments.

Conclusion: clean air is not a luxury, but a duty

Healthy air in production is a decisive success factor today – not only for health protection, but also for process safety, fire protection and machine availability. If you want to protect your employees, machines and production quality, there’s no getting around machine tool air cleaners.

And: the technology is there. It works. All you need is the will to use it – and the knowledge of why.

YouTube video with a webinar recording on the subject of “Machine tool air cleaners”.

Also available as a podcast episode: