Inhaltsverzeichnis

- Effective air purifiers against the deadly oil mist from machine tools

- Oil mist separator Air purifiers remove deadly oil mist

- Avoid dangerous oil fires

- No deadly oil mist and no dangerous vibrations!

- Further information and detailed product data can be found in our current REVEN ePaper on the elimination of deadly oil mist:

- Curious? Interested in more information?

- Follow us on social media

Oil mist and smoking can be deadly, information for metalworkers. Why do you prohibit smoking in your production and allow the inhalation of oil mist and aerosols?

Do you think the existing ventilation provides sufficient protection? This is a fallacy, because it is the invisible ultra-fine particles that are so dangerous: free-floating aerosols with a droplet diameter of less than 3-5 μm. The so-called oil mist from machine tools can be deadly! These dangerous aerosols enter the lungs and therefore the blood through breathing.

Only highly effective separators are able to remove them reliably. So play it safe and choose a separation process that reliably removes a whole spectrum of pollutants in addition to these fine particles: mist, vapors, gases, dust and smoke. A process that allows your employees to breathe fresh air, increases structural fire protection and also keeps the hall and machines clean.

Effective air purifiers against the deadly oil mist from machine tools

We won’t leave you standing in the fog! Measurements by the Fraunhofer Institute prove: Oil mist separators with a flow-optimized profile achieve degrees of separation of 98 % for critical particle sizes below 3-5 μm. This puts an end to the toxic fumes in the hall, grease-soaked exhaust air ducts, oily steel beams and windows. According to the recirculation principle, the air can also flow back into the hall because it is free of pollutants. Another result of Fraunhofer’s series of measurements: The degrees of separation are constant over time! There are neither mats nor foams that become dirty, build up pressure, slowly but steadily decrease in their degree of separation until they are saturated and then begin to emit themselves.

Oil mist separator Air purifiers remove deadly oil mist

Avoid dangerous oil fires

Thin lubricating and cutting oils form dangerous fire hazards, especially in machines that use pure oil as a cooling lubricant. Therefore, choose flame-arresting oil mist separators and pay attention to the corresponding test mark. The X-Cyclone separators from REVEN not only have the corresponding TÜV test sticker, but also the UL and DIN test mark. Not without reason: the American UL standard 1046 and the new European DIN EN 16282 are the world’s strictest test standards for protection against flame transmission. No wonder, because there is nothing Americans fear more than bacteria, communists and fire 😉

No deadly oil mist and no dangerous vibrations!

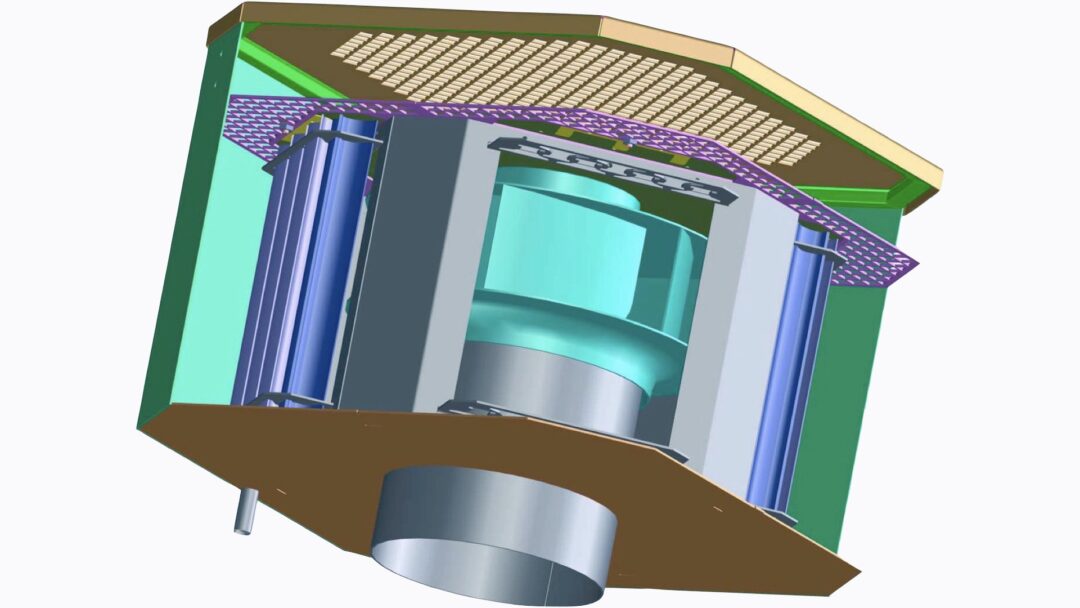

Shake-free rotary separators thanks to the REVEN X-CYCLONE separators! This technology is also part of the proven RECOJET RJ rotary separator. Despite its compact design, the RECOJET RJ can be equipped with up to four separator stages – depending on the customer’s requirements. With the RECOJET RJ separator and air cleaner, you eliminate the typical problems of conventional rotary separators with filter inserts, namely uneven running with vibrations. With the RECOJET, only the dynamically balanced fan rotates and not the entire drum. It is therefore quiet and vibration-free and saves a huge amount of energy, as much more economical fans are used. Also available in a mini version for small machine tools.

Further information and detailed product data can be found in our current REVEN ePaper on the elimination of deadly oil mist:

Curious? Interested in more information?

Then simply contact our air purifier consulting team with specialists from the mechanical engineering sector:

- Bavaria Sascha Kess kess@kk-wzm.de

- Baden-Württemberg & Hesse Andreas Pfeiffer pfeiffer@reven

- East Germany Heiko Dietrich h-d-w-gera@web.de

- North Rhine-Westphalia & Northern Germany Alexander Rohjan a.rojahn@pomagmbh.de

- Switzerland Matthias Reutimann urtec@urtec.ch

- Austria Gerald Fraissl gerald.m@tooltechnik.com

You can fill out this oil mist checklist to prepare for a consultation: