Inhaltsverzeichnis

- 1) Air pollution control in mechanical engineering: why it is so important

- 2) Air pollution control in mechanical engineering: how we capture and extract correctly

- 3) Air pollution control in mechanical engineering: separation instead of filtering

- 4) Air pollution control in mechanical engineering: how we save costs and improve sustainability

- 5) Air pollution control in mechanical engineering: decentralized and centralized combination

- 6) Air pollution control in mechanical engineering: step by step

- 7) What we take with us

- Call to Action

- Follow us on social media

Air pollution control in mechanical engineering: We protect people, machines and costs! Air pollution control in mechanical engineering is not a luxury, but a necessity. It protects employees from pollutants, keeps machines running reliably and reduces operating costs. In our live webinar, we showed why air pollution control is essential, how to correctly record emissions and how to safely separate pollutants from the air.

🎥 YouTube recording: https://youtu.be/tt-0F-WJsKQ

📥 Download: Presentation & clips: https://reven.link/keynote25d

💌 S ubscribe to newsletter: https://reven.link/newsletter

👤 Sven Rentschler on LinkedIn: https://reven.link/sr

1) Air pollution control in mechanical engineering: why it is so important

Machine tools produce mist, aerosols and vapors – and these pollute the air massively. Without air pollution control, there is an increased risk of people breathing in harmful substances without protection.

However, it is not only health that suffers, but also the machines themselves. Fine aerosols penetrate electronics, sensors and spindles, causing expensive damage. In addition, residues are deposited in buildings, increasing the fire load.

This is why air pollution control in mechanical engineering protects people, systems and buildings at the same time.

2) Air pollution control in mechanical engineering: how we capture and extract correctly

We can only extract what we capture. That’s why we move the intake points directly to the source of the emissions.

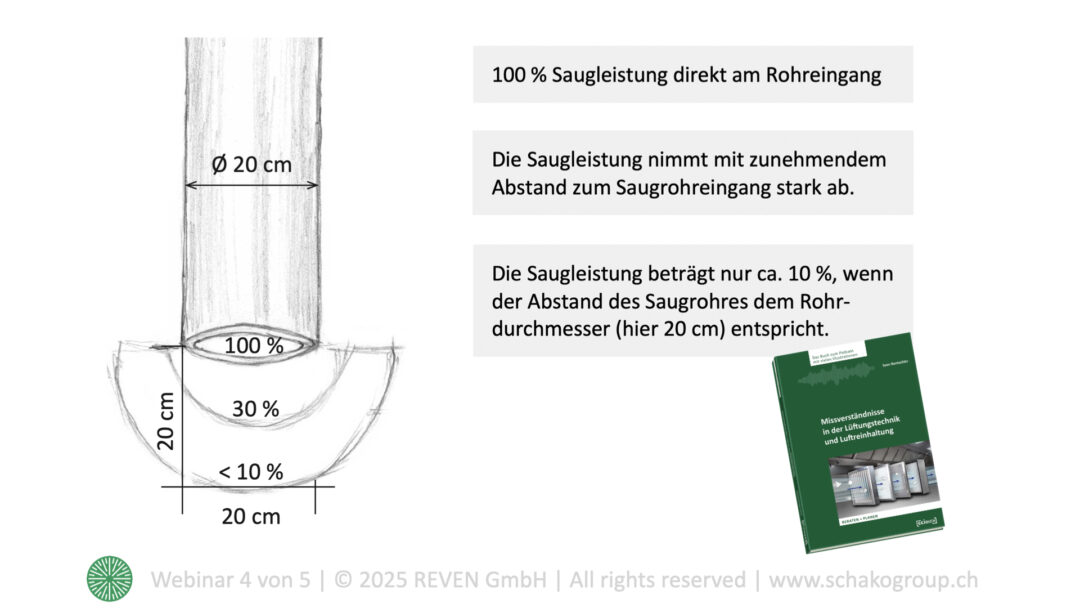

- We place pipes, nozzle plates and funnels as close as possible to the processing point, because every centimeter of distance drastically reduces the suction power.

- We consciously plan flow paths so that air is always routed via the relevant process.

- We rely on moving detection hoods for large machines because this is the only way to keep the distance constantly short.

- And if it is not structurally possible to capture the air directly, we program door openings with a delay so that the air in the interior is extracted first.

Example: If the intake opening is two meters away from the milling cutter, the mist immediately flows into the room when the door is opened. That’s why we change the geometry or control the exhaust air intelligently to prevent clouds of mist.

ℹ️ Info box: Understanding suction power

👉 100 % suction power: directly on the pipe. 30 % suction power: even at a distance of half the pipe diameter. < 10 % suction power: as soon as the distance corresponds to the pipe diameter. ⚠️Darum: Always capture as close as possible!

3) Air pollution control in mechanical engineering: separation instead of filtering

Once we have captured pollutants, we have to separate them from the air. Many people rely on filters for this, but they store liquid and this is exactly what leads to problems.

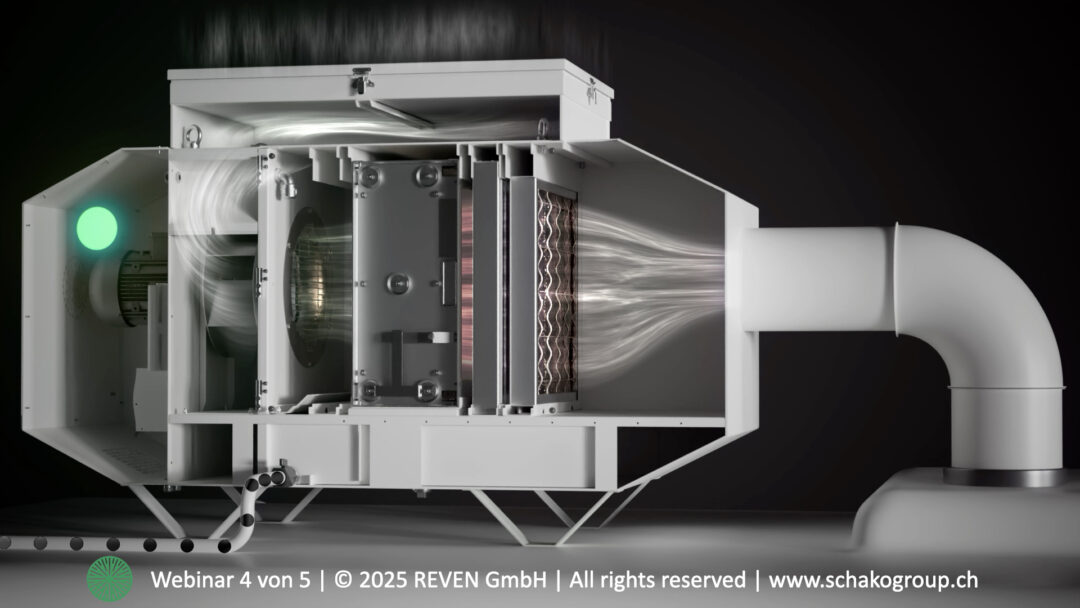

That’s why we rely on separators

- Separators do not store liquid, but return it directly to the circuit.

- This considerably reduces the fire load, as stored oils and emulsions always increase the risk.

- We also save on operating costs because we don’t have to replace and dispose of cassettes.

Why HEPA filters do not fit here

HEPA filters originate from cleanroom technology. They are perfect for bacteria and microorganisms, but completely unsuitable for oily aerosols. They clog up quickly, drive up costs and increase the risk of fire.

The following therefore applies: A HEPA filter can only be useful in niche cases – if smoke particles remain, for example. As a rule, a well-planned separation system is completely sufficient.

How we separate pollutants

- Mechanical separators (e.g. X-CYCLONE) separate robustly and permanently.

- Stainless steel mesh agglomerates the smallest particles so that we can separate them efficiently.

- Electrostatic stages capture the finest aerosols < 1 µm and return liquid.

ℹ️ Info box: Check fire load

👉 Many filter systems store up to 100 kg of liquid per filter cassette. These liquids often consist of oil or highly flammable emulsions. ⚠️Gefahr: Each filter thus becomes an additional fire load. Test question: How many filters are there in the hall? Multiply the number × stored liquid – and the real fire load becomes visible. Solution: Use separators without storage media to completely eliminate this hidden danger.

4) Air pollution control in mechanical engineering: how we save costs and improve sustainability

In terms of investment, filter and separator systems are usually on a par. But when it comes to operating costs, everything is different.

- Filter systems cause follow-up costs due to cassette replacement, disposal and downtime.

- Separators save these costs because they work without storage media.

- They also ensure sustainability, as coolants and lubricants remain in the cycle instead of ending up as waste.

The technology is also impressive in terms of occupational safety, as waste and fire load are reduced.

5) Air pollution control in mechanical engineering: decentralized and centralized combination

In practice, we use two methods and often combine them:

- Decentralized: We place air cleaners directly on the machine. The air is cleaned and blown back in above the machine. Heat recovery plays no role here.

- Central: In large companies, we conduct the exhaust air via air handling units. Here, we use separators as duct elements and utilize heat recovery, which is even mandatory for certain volume flows.

- Best practice: We remove the main load directly from the process and stabilize the hall air centrally with heat recovery, temperature control and fresh air.

6) Air pollution control in mechanical engineering: step by step

- We measure emissions and define target values.

- We plan the acquisition as closely as possible.

- We dimension the extraction system with a view to energy and acoustics.

- We determine the separation, with separators, not filters.

- We check safety, fire protection, explosion, hygiene.

- We ensure operation with monitoring, feedback and documentation.

7) What we take with us

- We record as close as possible, because proximity counts more than cubic meters.

- We use separators to avoid fire loads and unnecessary costs.

- We examine the use of HEPA filters critically and only use them in exceptional cases.

- We plan with the machine manufacturers at an early stage to create perfect air flows.

- We combine decentralized and centralized and ensure energy efficiency with heat recovery.

Call to Action

🎥 YouTube recording: https://youtu.be/tt-0F-WJsKQ

📥 Download: Presentation & clips: https://reven.link/keynote25d

💌 S ubscribe to newsletter: https://reven.link/newsletter

👤 Sven Rentschler on LinkedIn: https://reven.link/sr